Main function

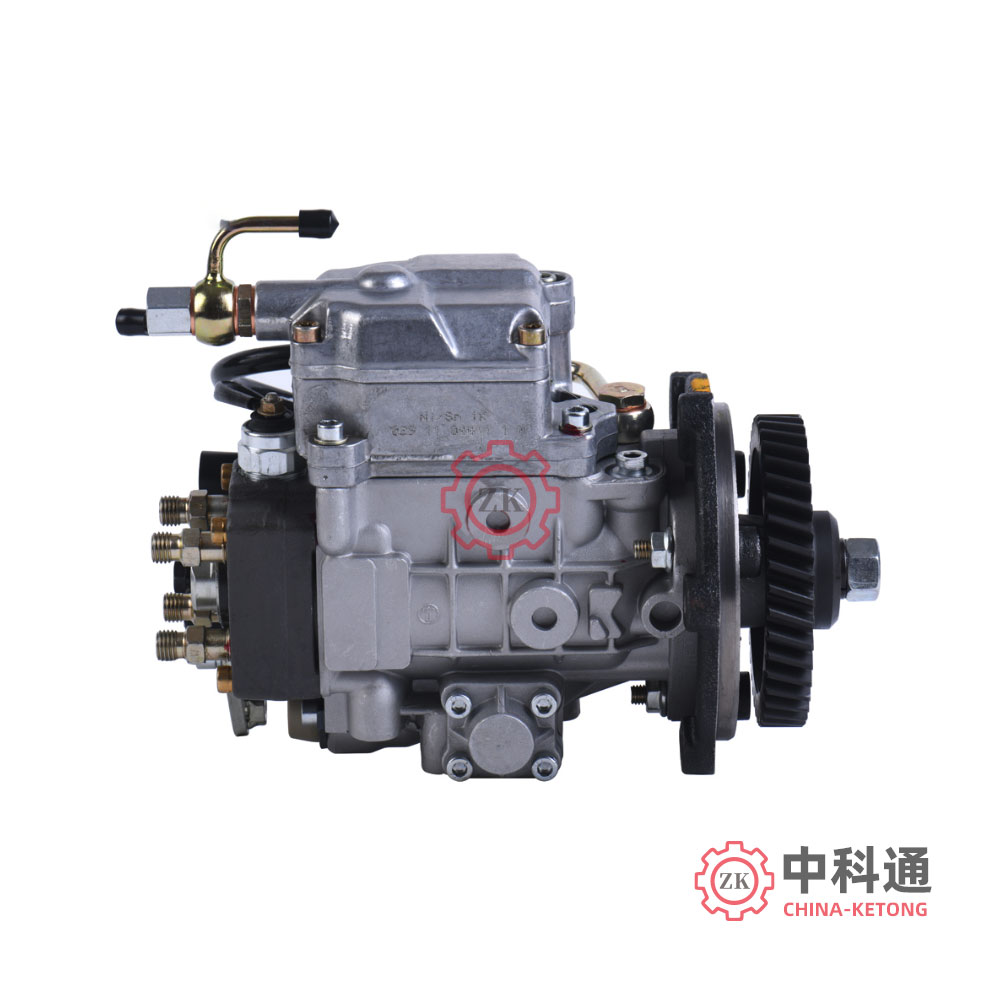

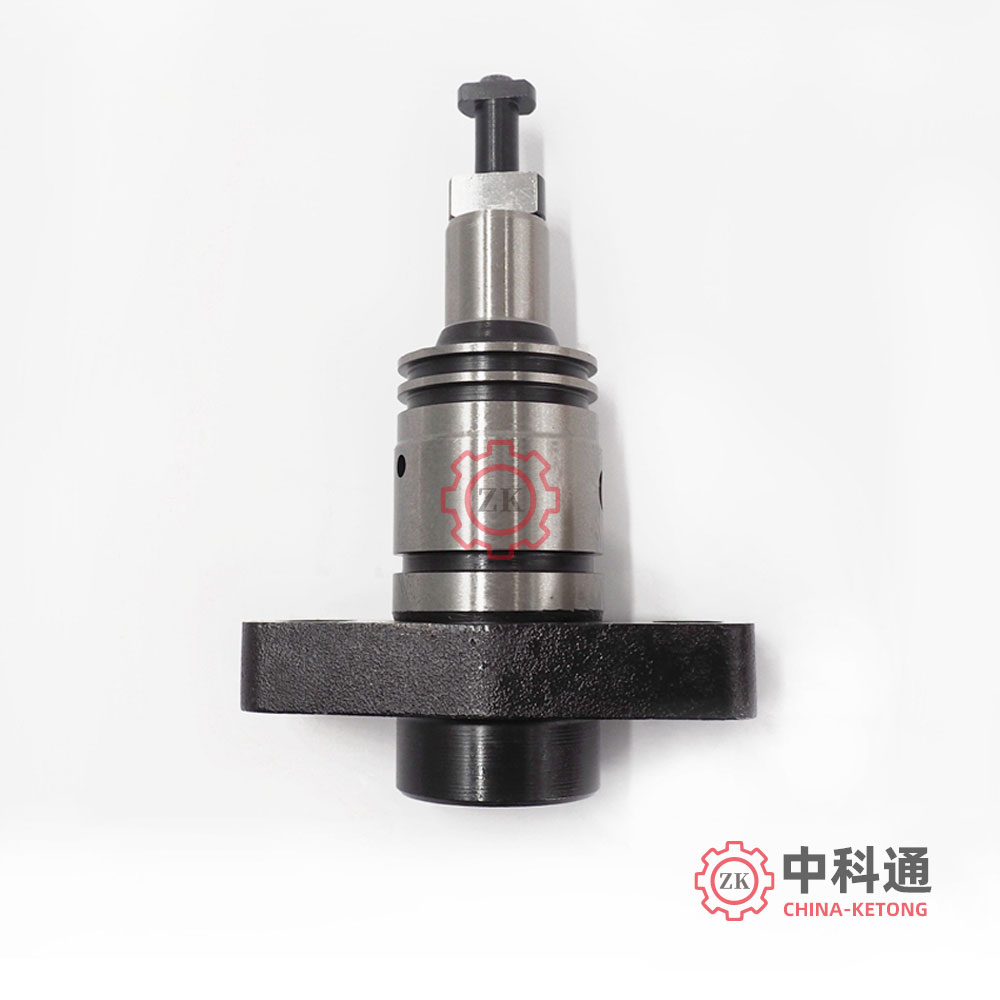

- Measurement of each cylinder delivery at any speed

- Test point and interval angle of oil supply of injection pump.

- Checking and adjust the mechanical governor.

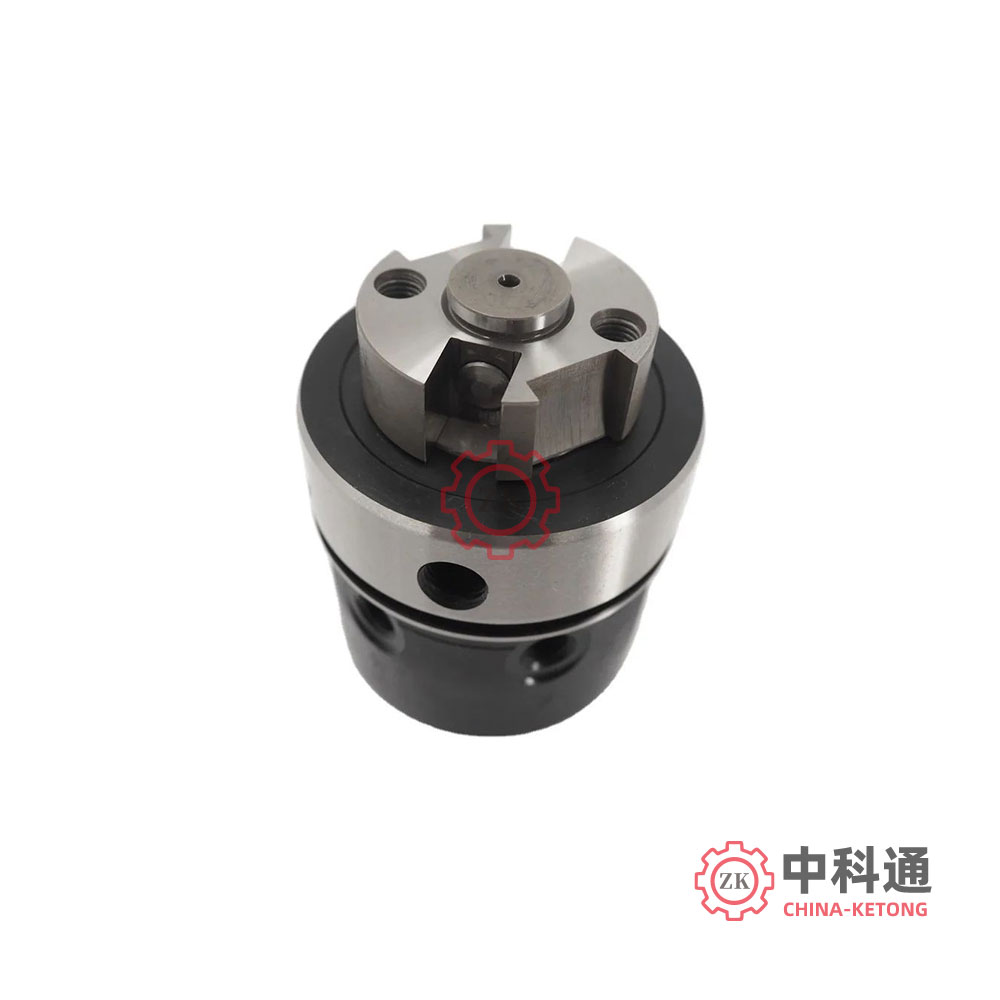

- Checking and adjusting the distributor pump.

- Experiment and adjusting of behavior of supercharging and compensatory device.

- Measurement of oil return of distributing pump

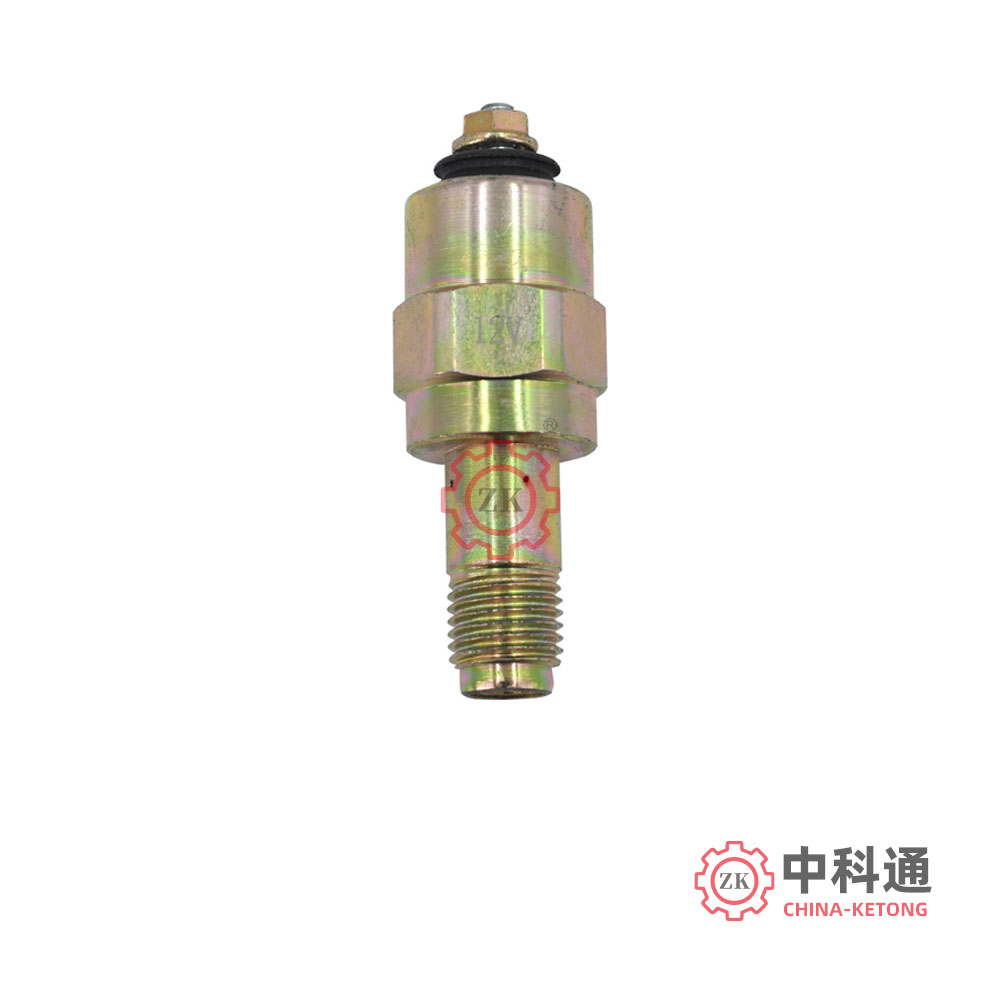

- Testing of the electromagnetic valve of distributor pump.(12V/24V)

- Measurement of the internal pressure of distributor pump.

- Checking of the advance angle of advance device.

- Checking the sealing of injection pump body

Characteristics

- Changing frequency changing rotational speed

- Low fall of rotational speed and high output torque

- High measurement precision;

- The functions of over voltage, overload and short circuit protection;

- Ten classes Rotation speeds presetting;

- Constant temperature controlled;

- Ultra low noise;

- Operating position: arbitrary side of the two work sides of the test stand;

- Rotation speed, count, temperature, air pressure digital display.

- Built-in air resource;

Technical Parameters

| No. | Items | Data |

|---|---|---|

| 1 | Main motor output power(kw) | 7.5/11/15/18.5 KW |

| 2 | Frequency Converter | QIDIAN |

| 3 | Stroke Counting (Rpm) | 50-9999 |

| 4 | Standard injectors | ZS12SJ1 |

| 5 | Power of fuel pump motor (kw) | 0.75 |

| 6 | Scope of rotate speed (r/m) | 0~4000 |

| 7 | Number of cylinders | 12 |

| 8 | Height of principal axis center (mm) | 125 |

| 9 | Filter oil precision of test bench(μ) | 4.5~5.5 |

| 10 | Volume of big and small volumetric cylinder(ml) | 150 45 |

| 11 | Volume of fuel tank(L) | 40 |

| 12 | DC power supply | 12/24V |

| 13 | Low pressure of fuel oil pressure(Mpa) | 0~0.4 |

| 14 | High pressure of fuel oil pressure(Mpa) | 0~4 |

| 15 | Pressure Gauge for VE Pump (Mpa) | 0-1.6 |

| 16 | Pressure Gauge for VE Pump (Mpa) | 0-0.16 |

| 17 | Control temperature of fuel (℃) | 40±2 |

| 18 | Flywheel inertia(kg*m) | 0.8~0.9 |

| 19 | Scope of rack bar stroke(mm) | 0~25 |

| 20 | Measuring range of flow meter(L/m) | 10~100 |

| 21 | DC electrical source(V) | 12 24 |

| 22 | Positive pressure of air supply(Mpa) | 0~0.3 |

| 23 | Negative pressure of air supply(Mpa) | -0.03~0 |

| 24 | Dimension of Packing ( L*W*H(m )) | 2.14*1.1*1.82 |

| 25 | Gross weight of Test bench( kg) | 700-800 |

PACKING LIST

| NO. | Name | Specification or Symbol | Quantity | Unit | Remark |

|---|---|---|---|---|---|

| 1 | Fuel Injection Pump Test Bench | 12PSB | 1 | Set | |

| 2 | Standard Injector | PB55ST42 | 12 | PC | |

| 3 | High Pressure Oil Pipe | M14×1.5/M14×1.5×600 | 12 | PCs | With it injector itself |

| 4 | High Pressure Oil Pipe | M14×1.5/M12×1.5×800 | 12 | PCs | |

| 5 | Small Graduate | 45ml | 12each | PC | |

| Big graduate | 150ml | ||||

| 6 | Feed(Return)Oil Pipe | M20×1.5×1000 | 2 | PC | |

| 7 | Oil pump connector | M14×1.5 M12×1.5 | 2each | PCs | |

| M16×1.5 | |||||

| 8 | Scale Lever | 1 | PCs | ||

| 9 | Rotational Joint | φ12.5 φ14.5 φ16.5 | 2each | PCs | |

| 10 | Versatile angle iron | 1 | Set | ||

| 11 | Coupler | ⅠⅡⅢ.IV | 1each | PCs | |

| 12 | Clamping Bracket | 1 | Set | ||

| 13 | T-type screw nail | 3each | PC | One of them longer | |

| 14 | Hexagon Wrench | S=10 | 1 | PCs | |

| 15 | Locating Block | ⅠⅡⅢP7, P7100 | 2each | PCs | |

| 16 | DC power supply wire | 12/24V | 1 | PCs | |

| 17 | Air Pipe assemble | 1 | SET |